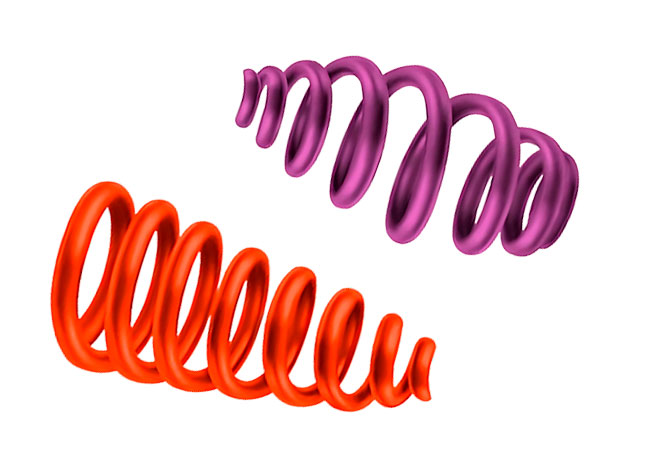

Barrel springs are a type of compression spring with a wider middle and narrower ends, making them look like barrels. This design gives them extra stability, better load handling, and helps save space. Because of these benefits, barrel springs are perfect for situations where regular springs might not work.

High-quality, customized barrel springs for your specific engineering needs.

At C & J Spring, we focus on making custom barrel springs that are reliable, durable, and perform well. Our barrel springs are great for use in cars, airplanes, farm machinery, and many other industries. The unique shape of our springs helps prevent them from bending out of shape, making them last longer and perform better.

Our advanced production facilities can make barrel springs that fit your exact needs, whether they need to be telescoping or non-telescoping. We prioritize quality and personalization, making us the best choice for all your barrel spring needs.

Barrel springs have unique advantages that distinguish them from regular compression springs. Their special barrel shape—wider in the middle and narrower at the ends—provides extra stability, saves space, and can be used in many different designs.

The unique barrel shape makes these springs less likely to bend or buckle, especially when regular springs need extra support. The wider middle section helps distribute pressure, allowing the spring to stay stable without needing extra support.

One major benefit of barrel springs is that they reduce solid height. This happens because the smaller coils at the ends can compress into the larger coils in the middle. This feature helps solve design problems with regular springs, where the coils can't compress further due to solid height restrictions.

One major benefit of barrel springs is that they reduce solid height. This happens because the smaller coils at the ends can compress into the larger coils in the middle. This feature helps solve design problems with regular springs, where the coils can't compress further due to solid height restrictions.

These unique features make barrel springs an excellent choice for many industries and applications.

"*" indicates required fields

Barrel springs are great for creating linear force while taking up less space. Many customers choose barrel springs over regular compression springs for several reasons:

Barrel springs are used in many different industries because of their versatility and efficiency. Here are some common applications:

Here's how it works:

At C & J Spring, we use a precise three-step process to manufacture barrel springs that meet your exact needs. Our expert engineers work closely with you to ensure each spring is produced to exact specifications and gives you the expected performance.

Our process begins with a custom design tailored to meet strict specifications. Our engineers use the latest technology to create barrel springs that suit your unique needs. With a range of wire sizes, materials, and shapes available, we can provide both telescoping and non-telescoping barrel spring options, ensuring reliable and consistent results.

After the design phase, our focus shifts to high-quality manufacturing. We carefully produce each barrel spring with precision, meeting the highest standards. Our manufacturing process combines advanced techniques with meticulous attention to detail to maintain consistency across every unit.

Every barrel spring undergoes thorough quality control and testing before it reaches you. Our strict protocols include testing for durability, load handling, and fatigue resistance, ensuring every spring exceeds industry standards. Our ISO certification reinforces our commitment to delivering the highest quality products to our customers.

Ordering custom barrel springs from C & J Spring is easy and efficient. Our team guides you through each step, ensuring your requirements are met, and you receive the best barrel spring for your application.

Our process begins with a personalized consultation. Our experienced engineers discuss your requirements, including material, size, and force specifications. This step ensures we fully understand your needs to design a barrel spring perfectly suited to your application.

Once we understand your requirements, our design team will create a custom barrel spring tailored to your specifications. Using advanced technology and expertise, we ensure a reliable, high-quality product that meets your expectations for performance and durability.

After production, we coordinate the timely delivery of your springs. Each barrel spring arrives on schedule, ready for immediate use, and backed by our commitment to quality and customer satisfaction.

Durable materials for reliable performance.

C & J Spring provides a range of high-quality materials for barrel springs, including:

Choosing the right material is important to make sure your spring works as expected.

Barrel springs are designed to prevent buckling, offer better load distribution, and save space. They provide a progressive spring rate, which helps with shock absorption.

To choose the right barrel spring, consider the load, available space, and environment where it will be used. Our C & J Spring experts are always ready to help you find the perfect solution.

Yes, we offer fully customizable barrel springs based on your specific needs, including the material, size, and force requirements.

The lead time depends on the complexity of the design and the specific materials used. However, we prioritize efficient production at C & J Spring to ensure timely delivery. We will provide an estimated timeline during your consultation.

Our barrel springs are manufactured to meet ISO-certified quality standards, ensuring they provide reliable performance and durability and meet industry requirements. Each spring undergoes strict quality control and testing before delivery.

Yes, we offer prototype services to help you evaluate the design and performance of your custom barrel spring before moving forward with full-scale production. This allows us to make any necessary adjustments to meet your specific needs.